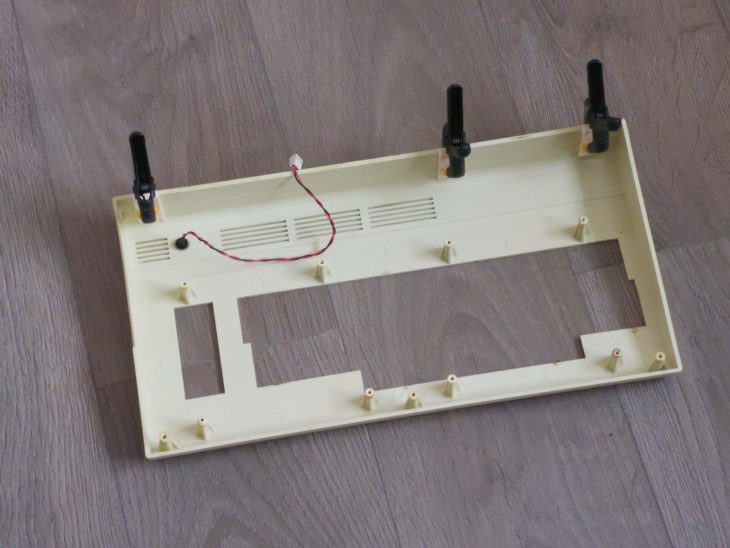

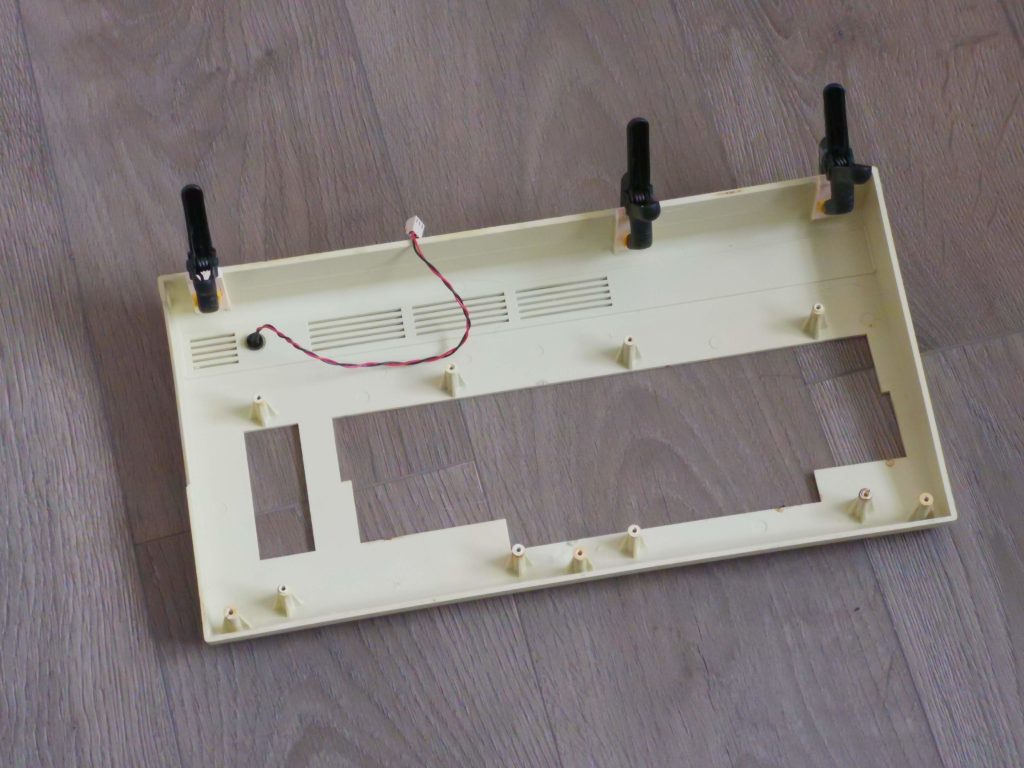

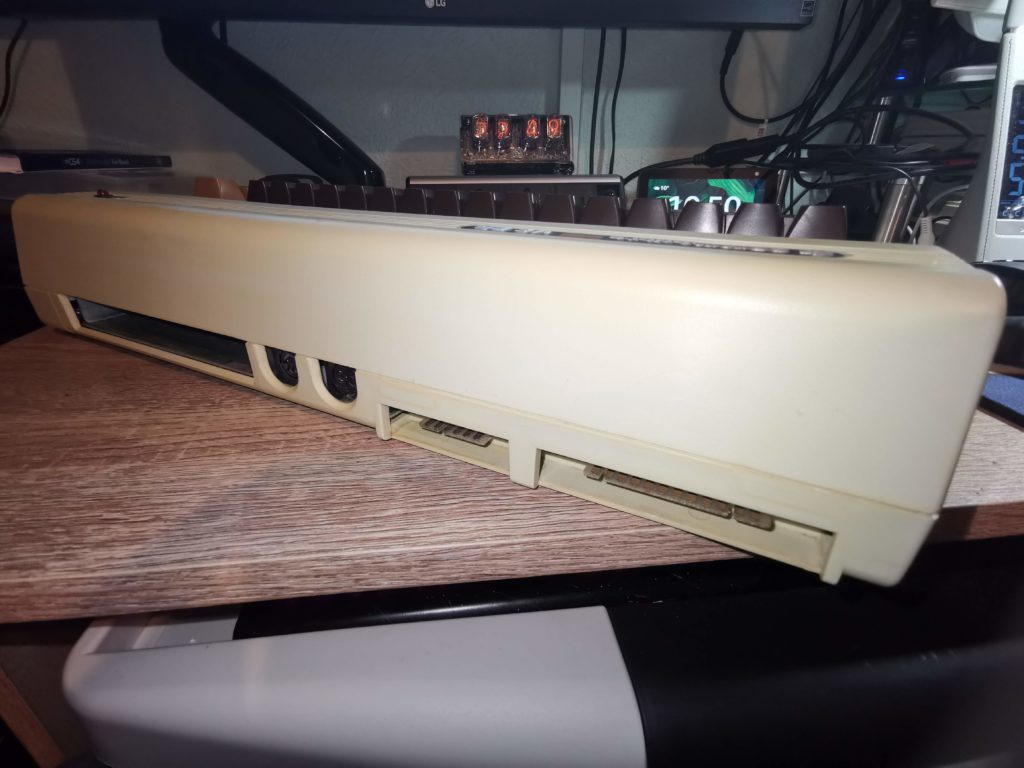

Whilst working on my VIC20 recently I noticed a number of issues with the case. The first thing was that most of the little tabs along the back of the lid had broken off. This meant that the case didn’t close properly along the back at all. The other issue I spotted was that a couple of the plastic screw posts that hold the keyboard in place had split. Not sure why, possibly as a result of over-tightening at some point or the plastic expanding and contracting over the years. It was pretty clear that my dear old Commodore VIC20’s case was in need of some repair and TLC.

By the way, even though this post is all about the VIC20 the contents would be just as valid for a Commodore 64.

Naturally I want my VIC20 to remain in as good a condition as possible so I set about looking for a means to remedy these problems. My search concluded when I came across a company in the US called Soigeneris that 3D prints suitable repair parts. The product I ordered from them was the ‘C64/VIC20 Case Saver Repair Kit‘. The whole thing cost me less than $20 including international shipping (which took about a week). *Note to self – get a 3D printer!

A look at what’s in the repair pack

Inside the pack there are actually 3 different parts to deal with common ‘breadbin’ case issues. New PCB standoffs (not needed here), replacement top case rear tabs and screw post repair sleeves. The drill bit is provided to help centre the PCB standoffs if you are using those.

From left to right: new PCB standoffs (with drill bit), replacement top case rear tabs and screw post repair sleeves.

There are several different case styles and they each have different types of hinge tabs. I had to check which variant mine was before ordering otherwise the replacement may not have fit. My particular VIC20 case needed ‘Type 2B’.

Fitting the new hinge tabs

I decided to fit the new hing tabs to the back of the upper case lid first. This necessitated completely removing what was left of the existing ones to make way for the replacements.

This was a simple matter of slicing the tabs off flush with the edge of the case. I used a sharp craft knife for this (and ended up slicing my thumb open) so do be very careful if you are following this post yourself. The plastic was a lot more brittle and softer than I expected so I applied way too much pressure…

Before proceeding any further I test fitted the tabs to make sure they fitted flush to the edge of the case. Where needed I shaved some more skin plastic off my with knife.

The replacement tabs are well constructed and have been designed to align easily within the existing channels.

The instructions recommend using epoxy glue to fix them in in place as it sets rock hard. It also recommends roughening the surface of the case and cleaning it with isopropyl alcohol before gluing to ensure maximum adhesion.

I applied a generous amount of epoxy glue and then held the tabs in position using some modelling clamps.

Even though my epoxy glue is supposed to be quick drying I set the case aside for 24 hours to fully harden before going any further.

Preparing the screw posts

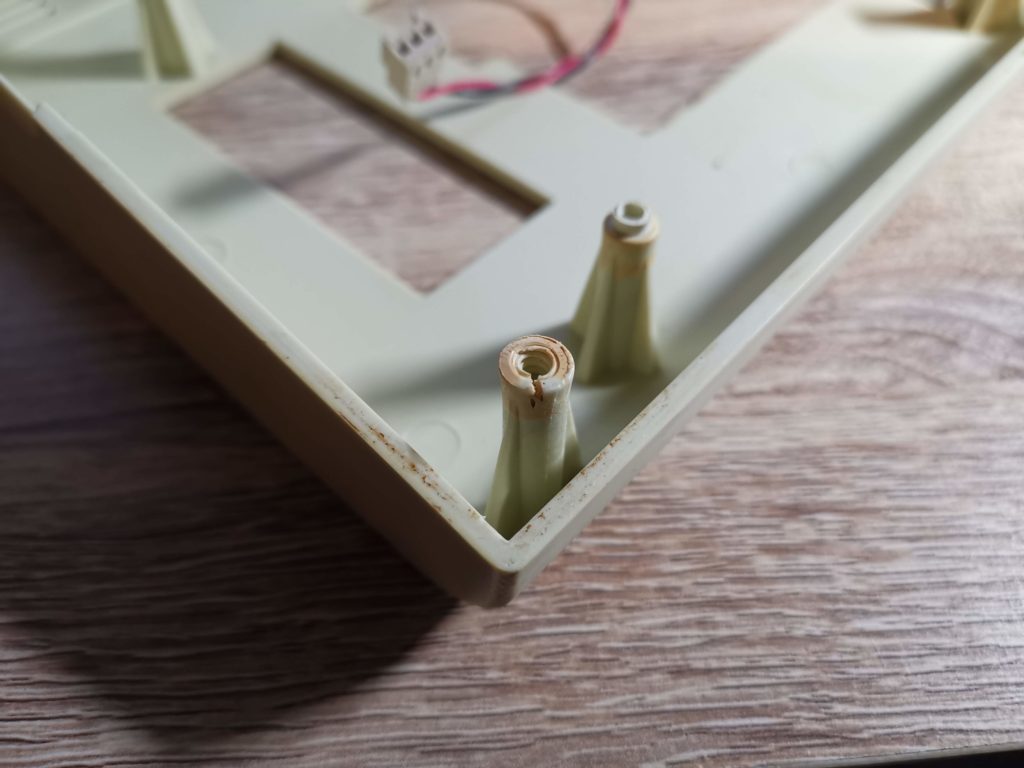

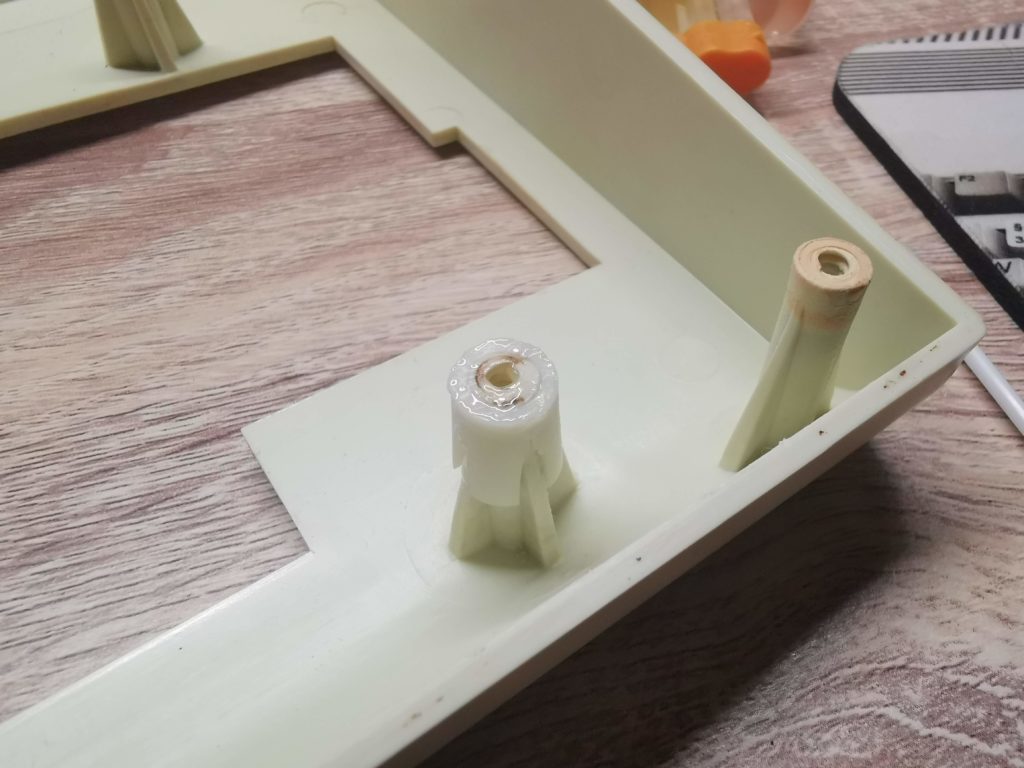

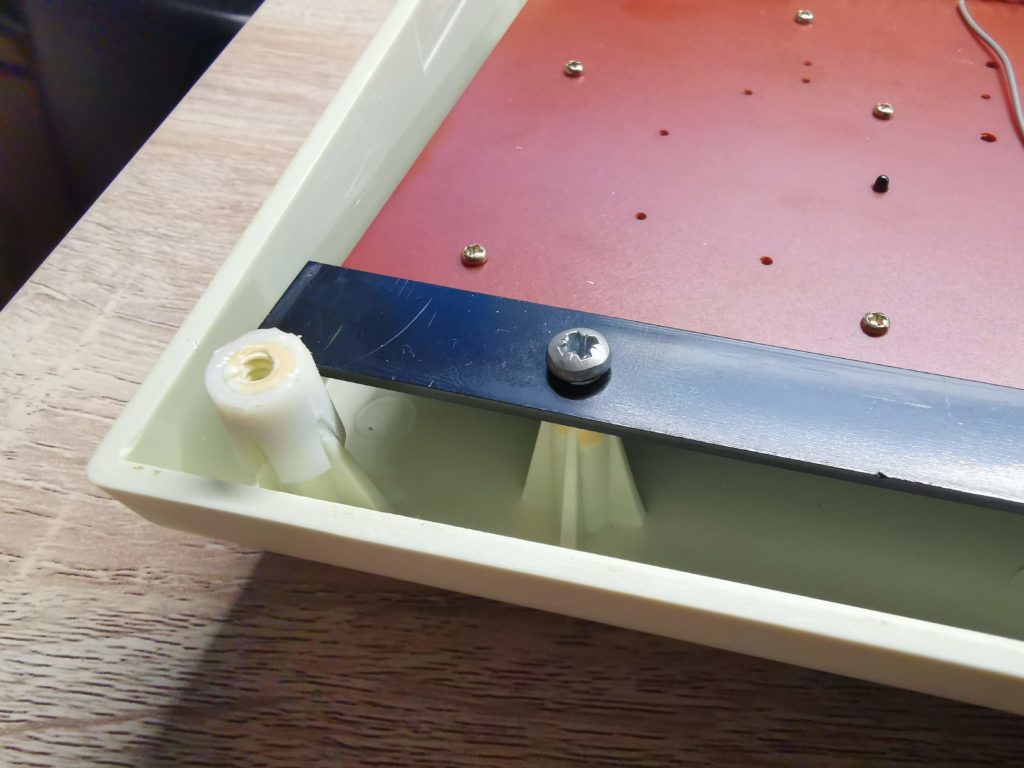

Once I was happy that the glue had fully hardened I moved on to tackling the split screw posts. Thankfully only 2 of the posts were damaged but the kit includes enough replacement parts to fix all of them if necessary.

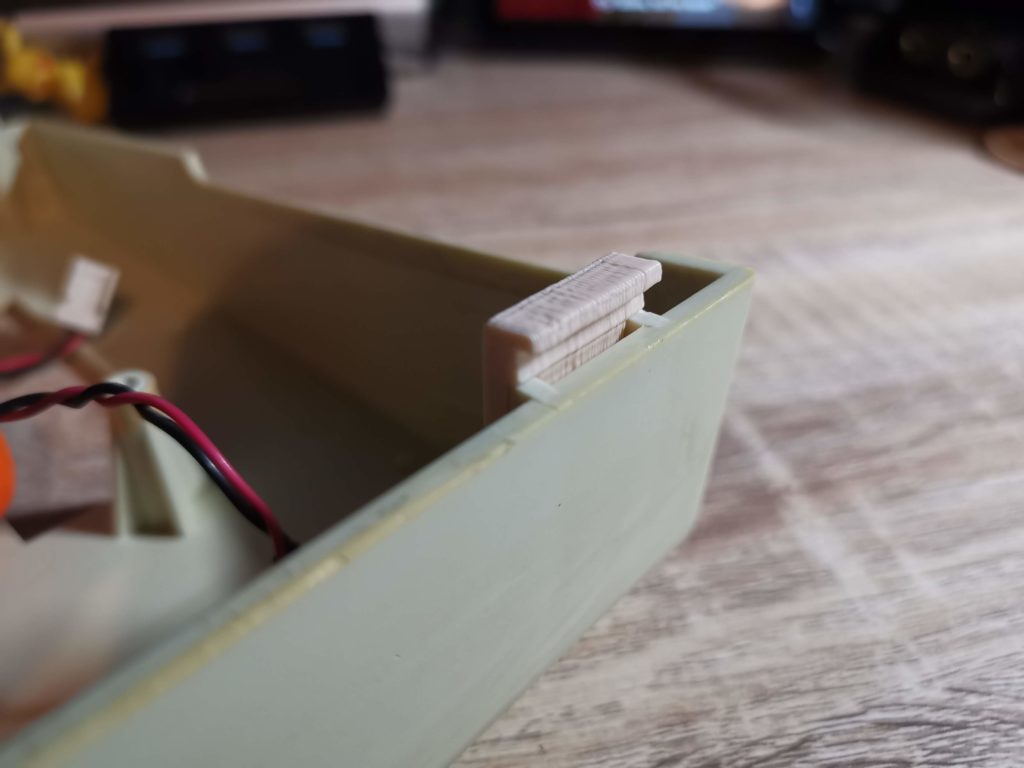

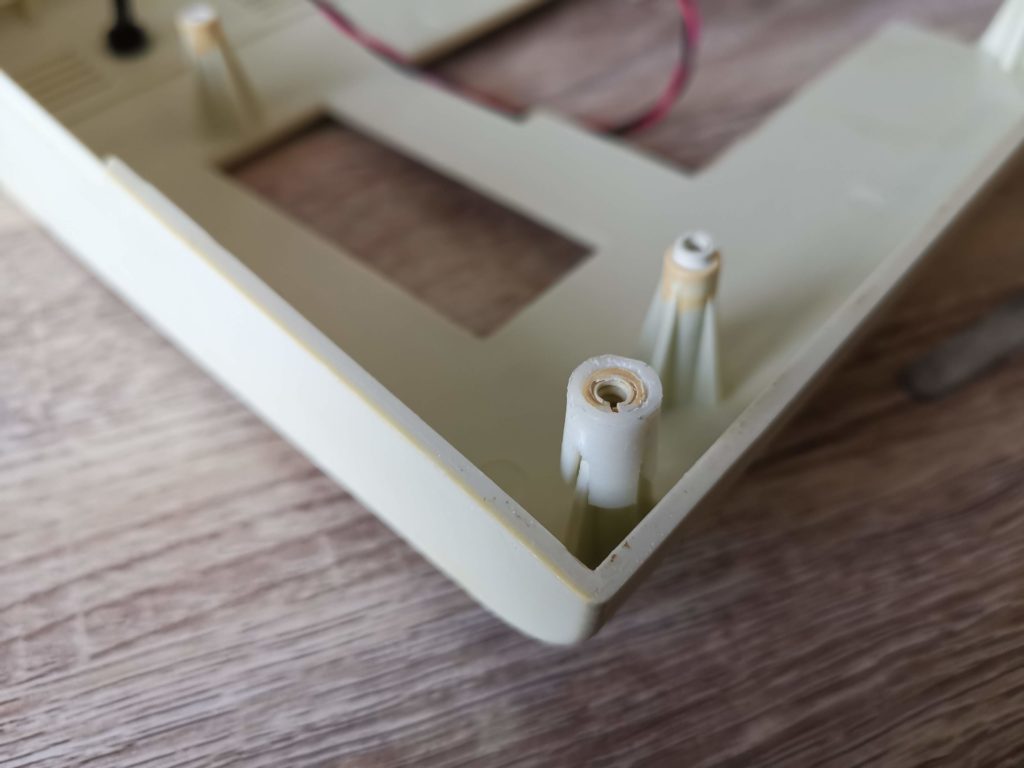

Not only was the screw post split but it had also ‘mushroomed’ out at the top. This meant that it would need to be filed down to it’s original size before the repair sleeve would fit over it.

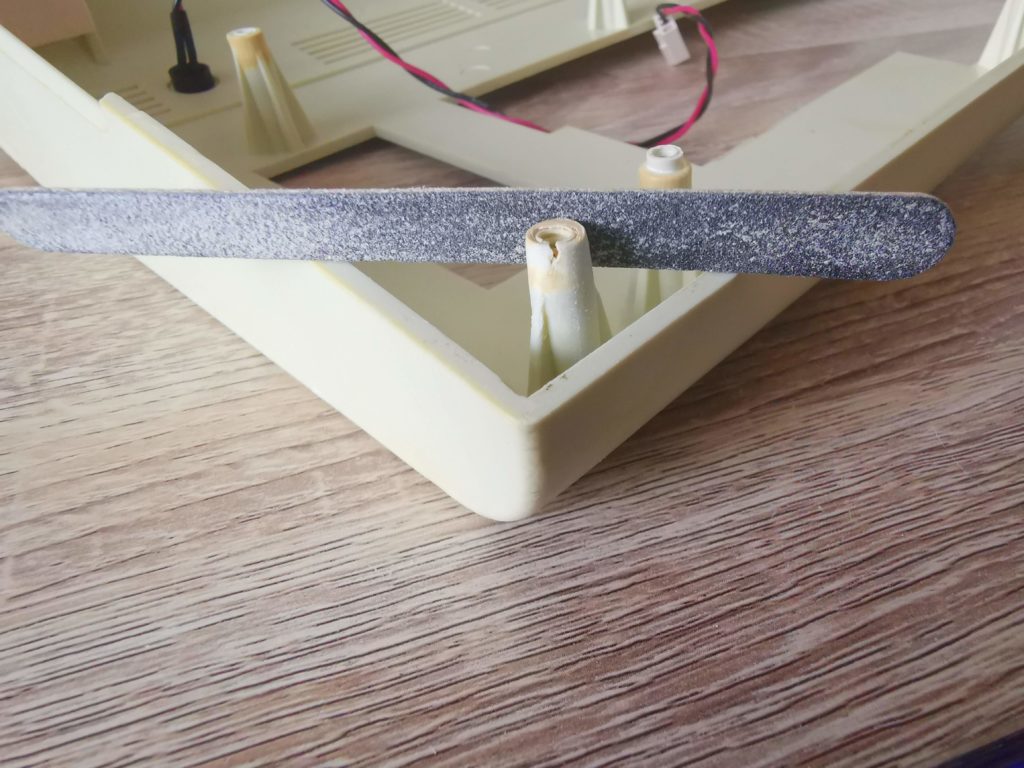

I used a few emery boards to sand the posts down to size but a small metal file would have done just as well. It took around 5-10 minutes to get it down to the correct size. I was constantly stopping and checking to see if the sleeve would fit. The last thing I wanted was to sand too much off and have the sleeve become loose.

Eventually I found the sleeve would slide into place with moderate force so I stopped sanding. Then I just needed to repeat the process on the other broken post before gluing both sleeves permanently into place.

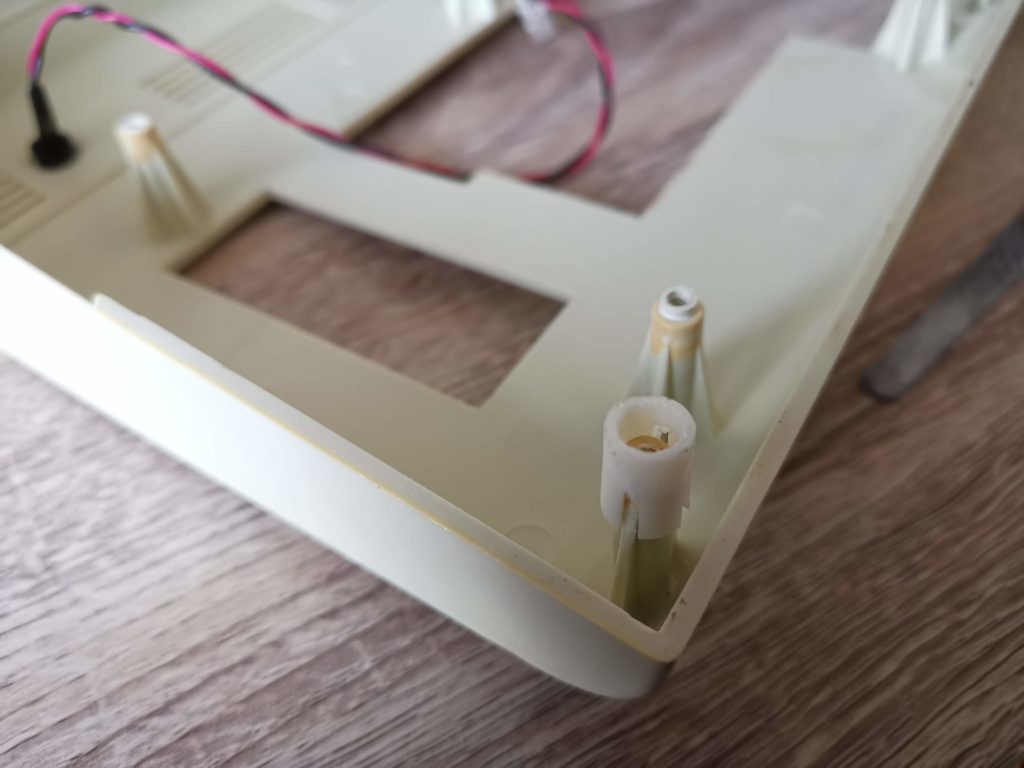

Gluing the repair sleeves

First I cleaned both the post and inside of the sleeve with isopropyl alcohol to make sure no plastic dust was left from the sanding. Then I mixed up a small amount of epoxy glue and applied it to the top of the post before sliding the sleeve down until the two top surfaces were flush.

I smeared a little extra epoxy on the top of both the posts to fill the splits in the plastic too. There was no need to use any sort of clamp this time as the sleeves were a tight fit. The friction alone was more than sufficient to do the job.

Once more the case was then set aside for 24 hours to give the glue ample time to harden.

Reassembly

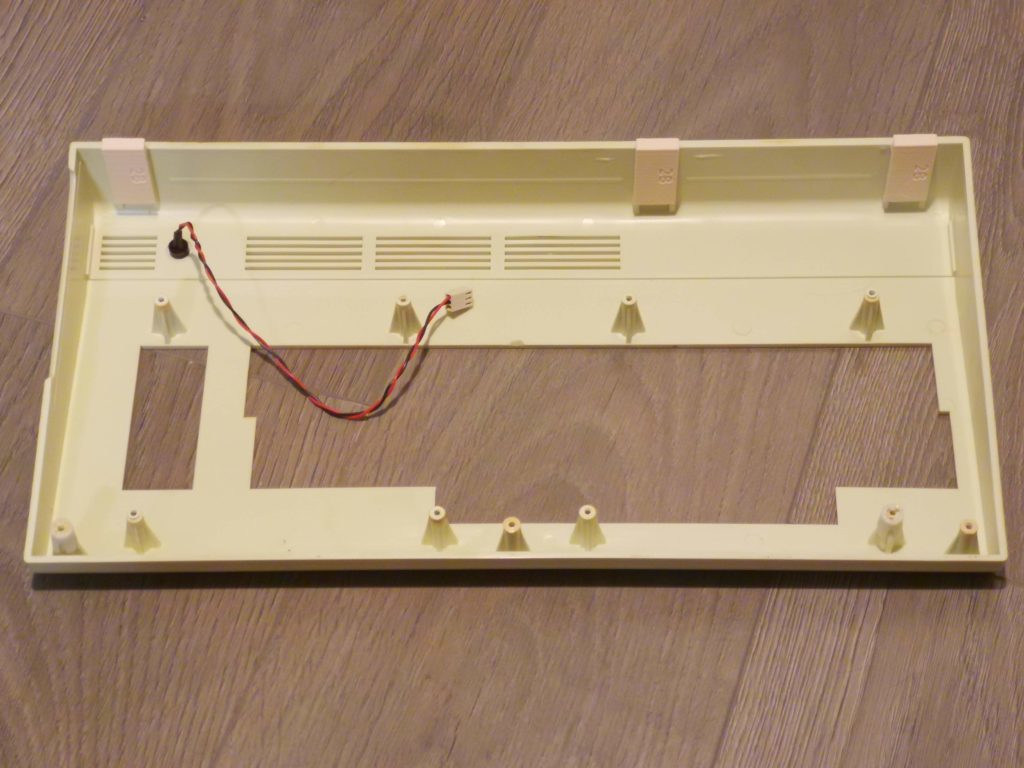

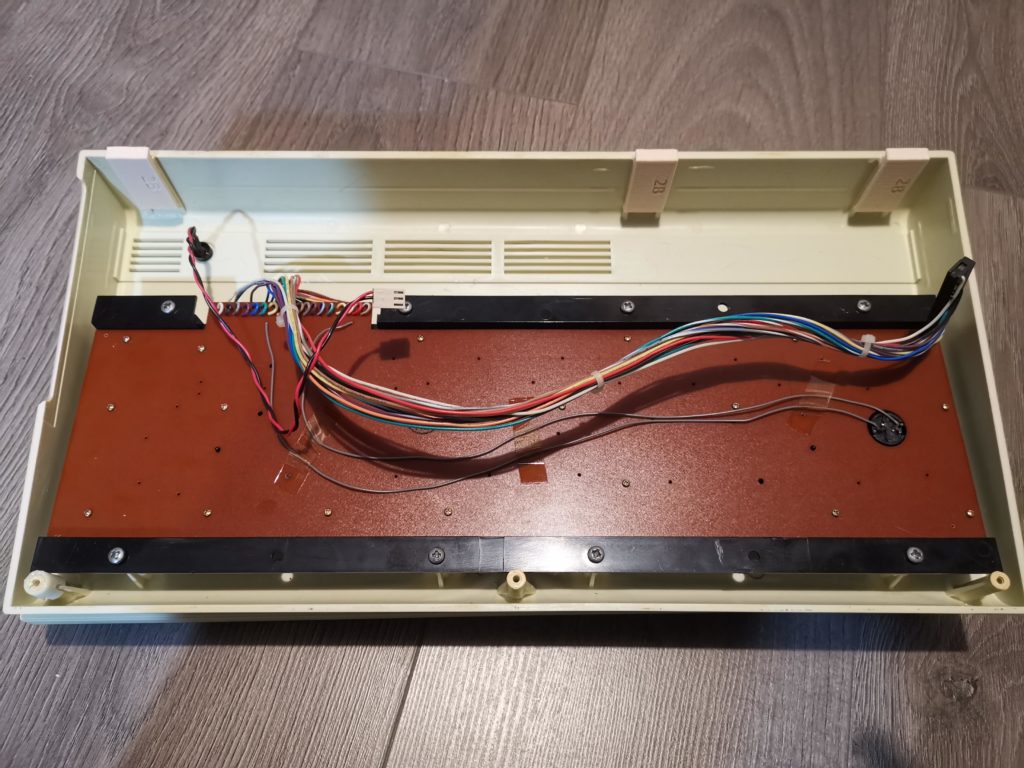

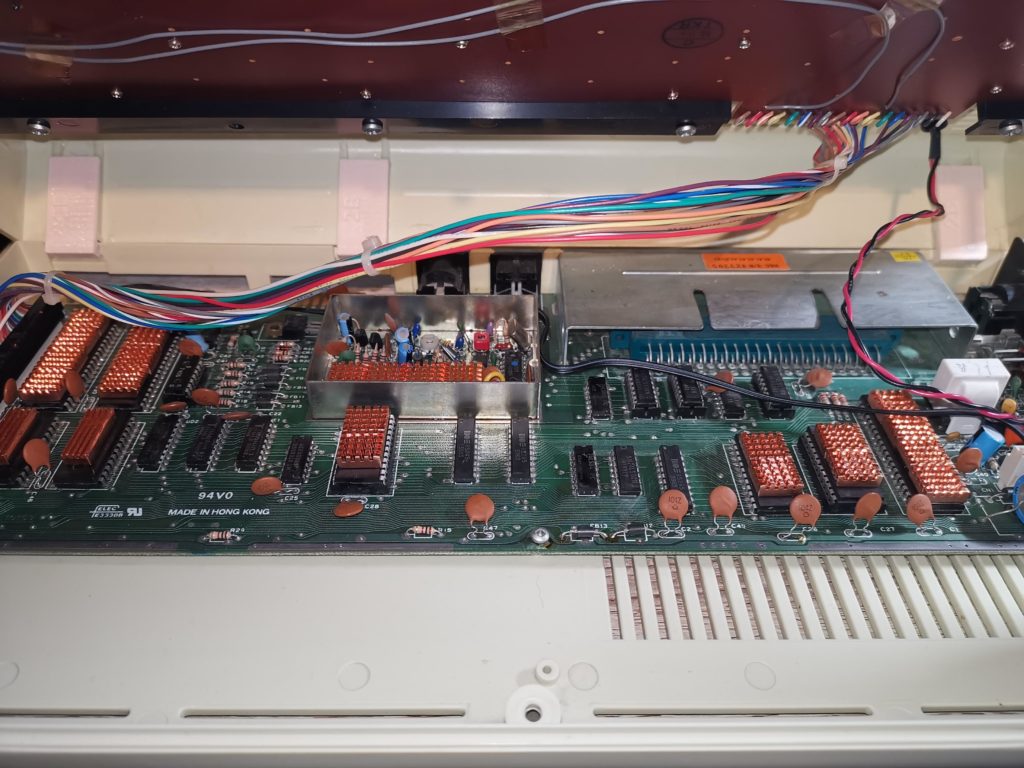

Now it was time to screw the keyboard back into place and to reunite the top and bottom parts of the case.

I must admit I was a little concerned that the added thickness of the sleeves might have prevented the keyboard from fitting correctly.

Happily, although a tight fit, the keyboard slotted into place without any extra trimming needed.

The screws went into the repaired posts without any issues and were held very securely.

The two halves of the case also fitted back together perfectly. The hinged tabs were very securely held by the epoxy glue and the little tongues aligned perfectly with the grooves on the bottom half of the case. The back of the case was held tightly closed, a vast improvement from how it was before the repair.

This turned out to be a very worthwhile, rewarding and cheap little project. The biggest cost was actually my time, both in preparing the case and making the actual repairs. The whole thing took me three evenings plus a couple of days of glue setting time.

Coupled with my heatsink project and keyboard repair my VIC20 is now in tip top condition again. Hopefully she will be able to take her upcoming 40th birthday in her stride as she marches on up to the big 50.

Discover more from Lyonsden Blog

Subscribe to get the latest posts sent to your email.